Orca Slicer for All OWLplane Models

Slicing All OWLplane Models Using Either PLA, LW-PLA,

PETG and ABS Whenever Applicable

Printing Using OrcaSlicer

When one gets a Bambu 3D printer, the first destination for slicing software is usually Bambu Studio, a 3D slicer developed specifically for Bambu FDM 3D printers. It has a user-friendly interface; however, if one wants advanced features and customization options, OrcaSlicer is the best choice in our experience.

OrcaSlicer is a free and open-source slicer made by a GitHub user called SoftFever, who forked it from Bambu Studio, and it is gaining popularity in the 3D printing community (see : https://www.tomshardware.com/3d-printing/how-to-use-orca-slicer).

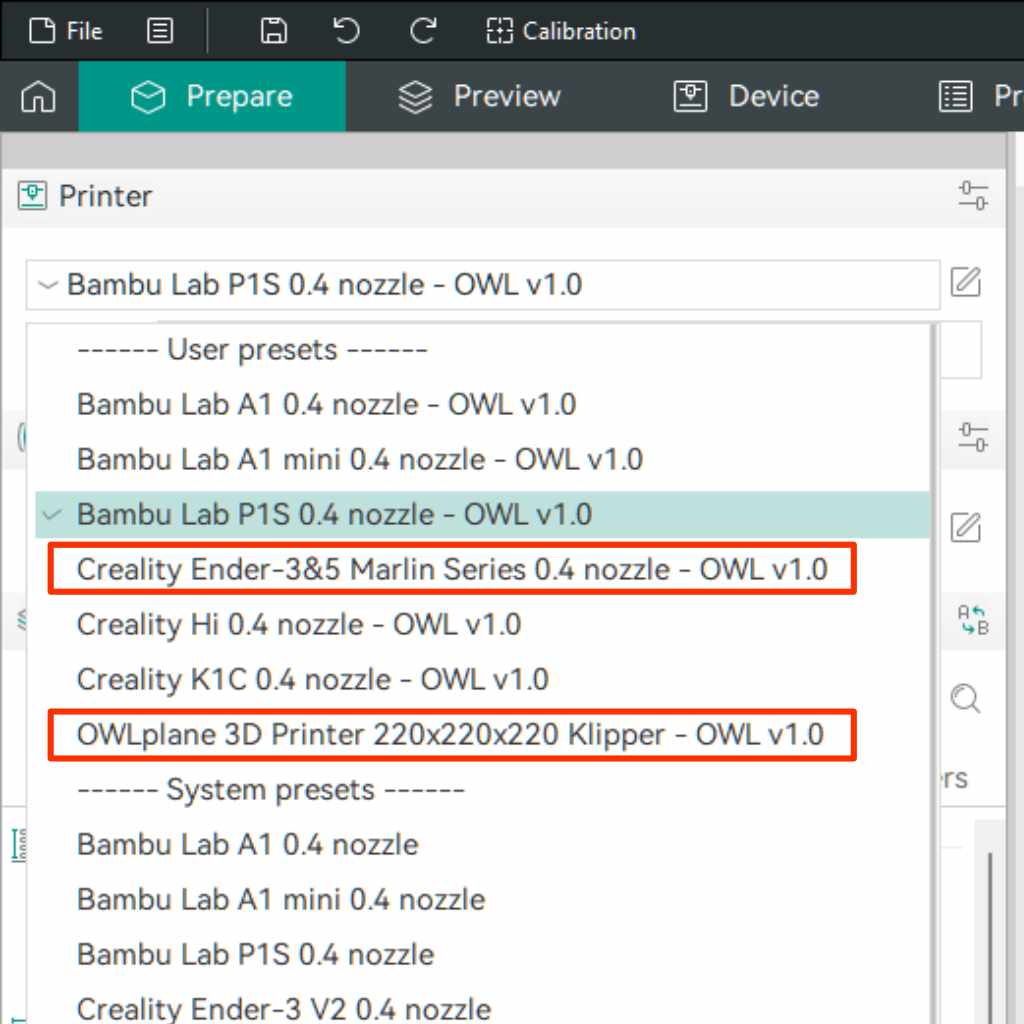

Another consideration to pick OrcaSlicer is that it is developed not only for BambuLab 3D Printers but also for other FDM 3D Printer brands such as Anker, Anycubic, Artillery, BambuLab, BIQU, Blocks, Chuanying, Comgrow, Creality, Elegoo, Elegoo, Flashforge, FLSun, FlyingBear, Geeetech, Kingroon, Luzbot, Prusa, Qidi, Ratrig, Snapmaker, Sovol, TwoTrees, Voron and many more. If your FDM 3D Printers are not in the list above, try to install and find your 3D Printers directly from the OrcaSlicer during installation. DIY 3D Printers using Klipper and Marlin firmware software are also supported. OWLplane provides a sample for Marlin firmware ( usually older 3D printers ) inherits from Creality Ender-3 v2 and a sample for Klipper firmware inherits from MyKlipper ( a system preset from OrcaSlicer). Both samples can be modified to match with your DIY 3D printer.

After evaluating both slicers, we have decided to use OrcaSlicer instead. Moreover, we have carefully evaluated OrcaSlicer for all of our earlier models and find out that the slicer can slice them correctly with no issue. In 2025, we decided to keep only one slicer for all models which is the OrcaSlicer.

There are some critical values that are intentionally hidden by Bambu Studio :

– Extra length on restart under filament setting group.

– Pressure advance under the filament setting group.

– Ensure vertical shell thickness under process setting group.

The three important settings above required when trying to get the best result for printing as a single perimeter model and also tweaking material extrusion for active foaming type of filament.

To download OrcaSlicer, please visit the following URL: https://github.com/SoftFever/OrcaSlicer and try to download by following the instruction. There are some recommended useful links that can be refer to learn Orca slicer:

Hints !

No Gcode provided starting 2025 onward but get used to print from OWLplane Gcode, what should I do?

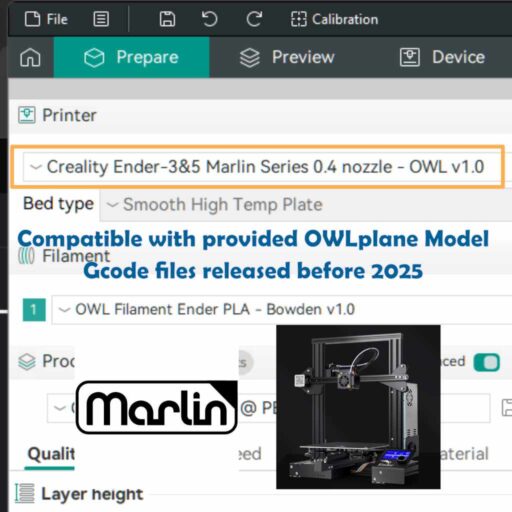

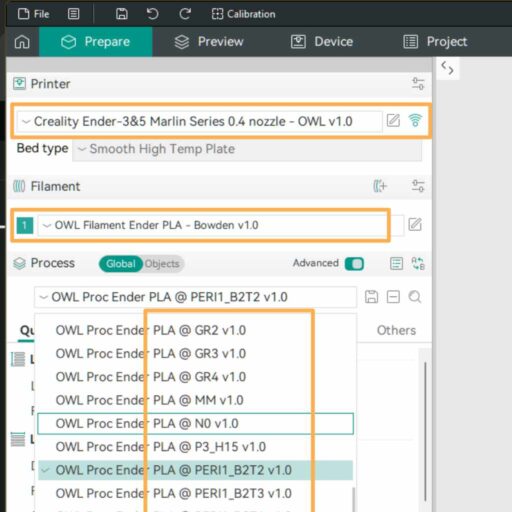

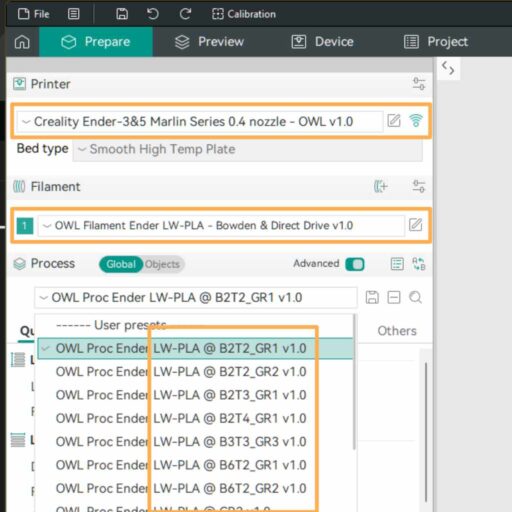

No worry, what you need to do is just to use Creality Ender-3&5 Marlin profiles. Both PLA and LW-PLA filaments are good to go using that profiles. OWLplane intentionally create Ender-3&5 Marlin Series 0.4 nozzle – OWL v1.0.

You can optimize the profiles by increasing the speed whenever your 3D printers can print faster for PLA filaments but for LW-PLA, you just may need to increase traveling speed instead.

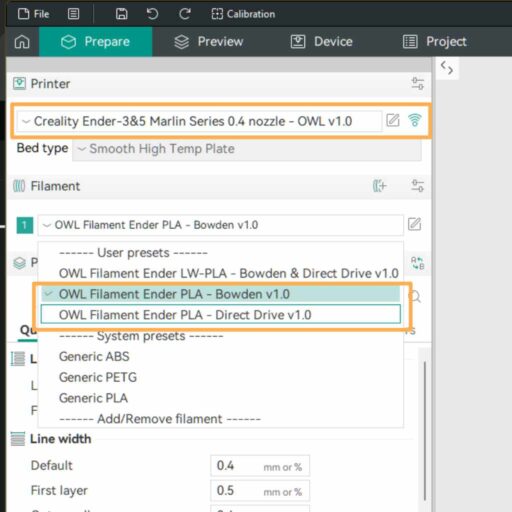

Please make sure you select what type extruder is your 3D printer. Please select accordingly Bowden or Direct Drive setup. Both options are available under “Filament” settings.

Always turn off Aux. Fan

It is enough to use cooling part fan during printing whenever necessary.

Let The Default Speed & Adjust It Via Volumetric (For Non-Active Foaming Filaments, Such As Standard PLA, PETG, ABS, Etc.)

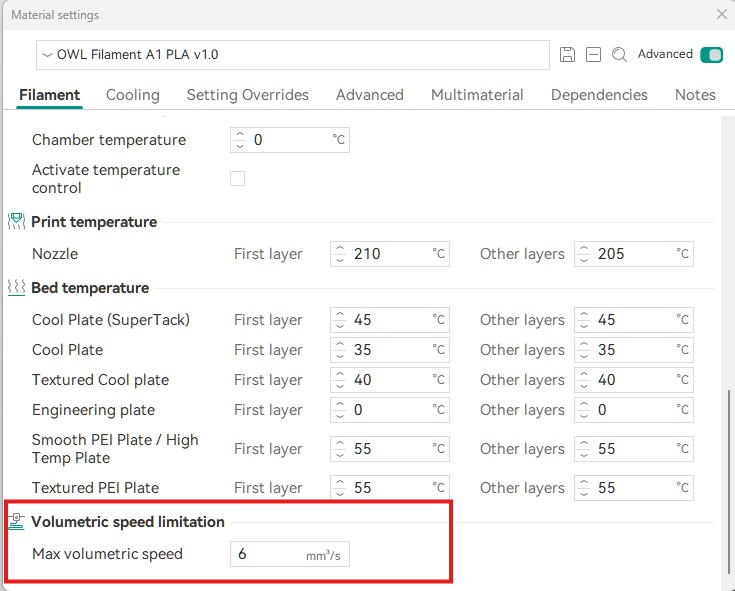

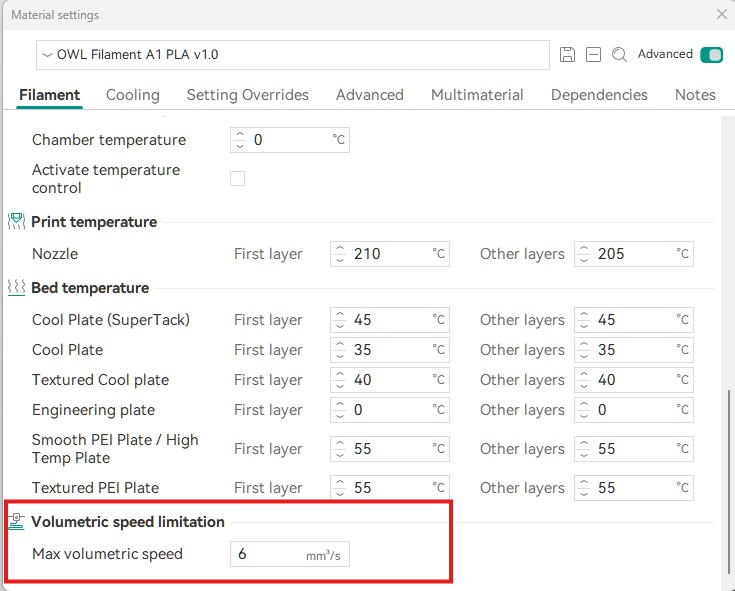

Decrease or increase the 3D printer speed via “Max volumetric speed” Filament tab under Filament setting for non-active foaming filament such as PLA, PETG or ABS to get the best and optimal result.

If you use “High Speed” type of filament, you may want to increase the speed by increasing “Max volumetric speed” setting.

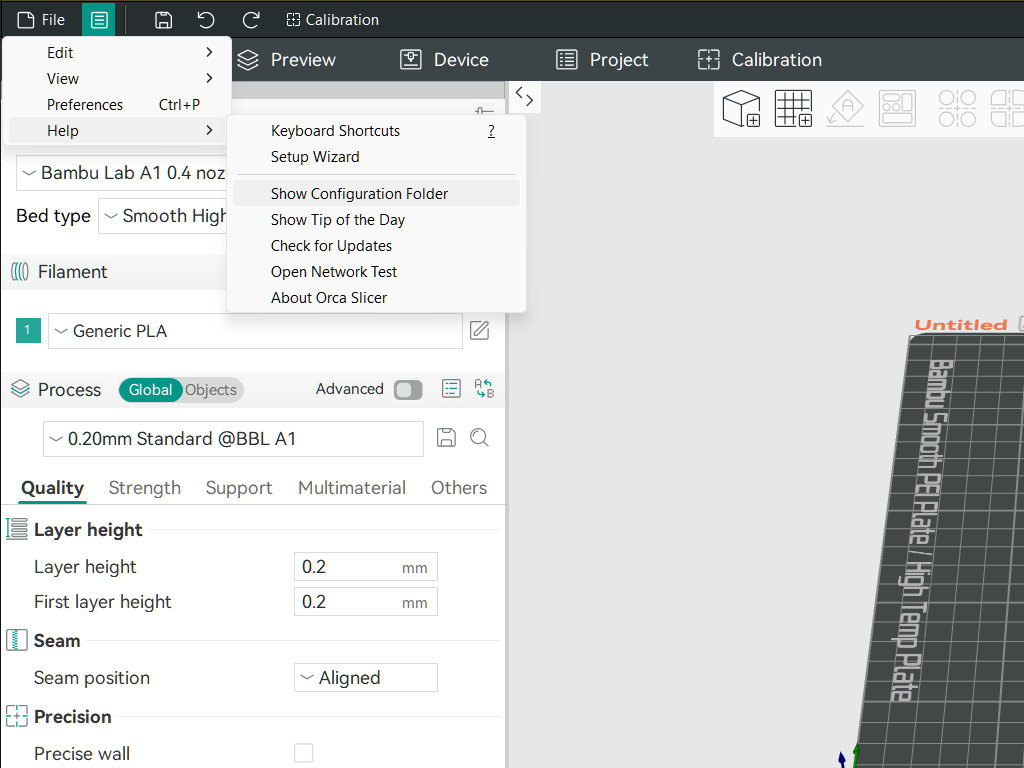

How To Install OrcaSlicer

Try to watch the right video if you would like to install OrcaSlicer by Teaching Tech.

For more information, try to watch the advanced guide presented by Teaching Tech.

Once you have installed OrcaSlicer, please include the base 3D Printers that are already defined as samples for printing OWLplane models otherwise when importing OWLplane profiles, they would not appear on the list.

Later, you can add your own 3D Printer brand and type and follow some values from the samples added above.

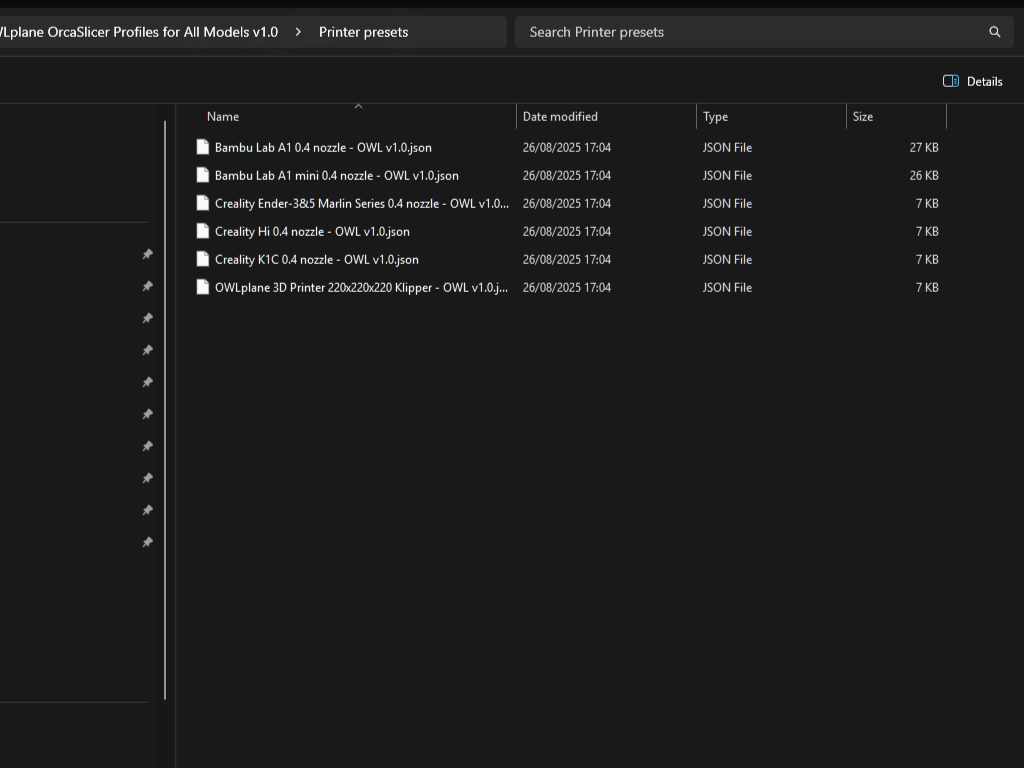

Provided 3D Printers as samples for slicing all OWLplane models are:

- BambuLab P1S,

- BambuLab A1,

- BambuLab A1 Mini,

- Creality Hi,

- Creality K1C,

- Creality Ender-3 v2,

- DIY Klipper 3D Printer.

If your 3D printer is not in the list, please try to set the same profile values whenever relevant for OWLplane models and type/brand of filament used; keep specific values to your 3D printer and type/brand filament used.

Note : If your printer is BambuLab P1S, also include the printer to add (we do not include in this video since when the video created the printer had not been acquired).

(1). Marlin Firmware - older 3D printers

For Marlin firmware and/or older generation/slow 3D printer with about 45 – 60mm/s outer perimeter speed, you may want to follow a sample from “Creality Ender-3&5 Marlin Series 0.4 nozzle – OWL v1.0” machine profiles. Feel free to increase the speed if your 3D printer still has capability to print without any issue.

(2). Klipper Firmware - newer 3D printers

Where Klipper firmware 3D printer with speed about 100 – 150mm/s or more (newly released 3D printers usually utilize Klipper firmware), you may need to follow a sample from “OWLplane 3D Printer 220x220x220 Klipper – OWL v1.0” machine profile.

Understanding Machine, Filament and Process

3 Elements in OrcaSlicer determine how OrcaSlicer slices the STL files. They are :

– Machines/3D Printers information such as bed and maximum height sizes (3D printed volume), firmware information, extruder characteristics, etc.

– Filaments type information that are configured for the Machines/3D Printers above such as min, max and operation hotend temperatures, fan cooling power, cooling time, material flow ratio requirement, etc.

– Processes show how the machine works in regard to layer width, layer height, hotend move and travel speed during printing, etc.

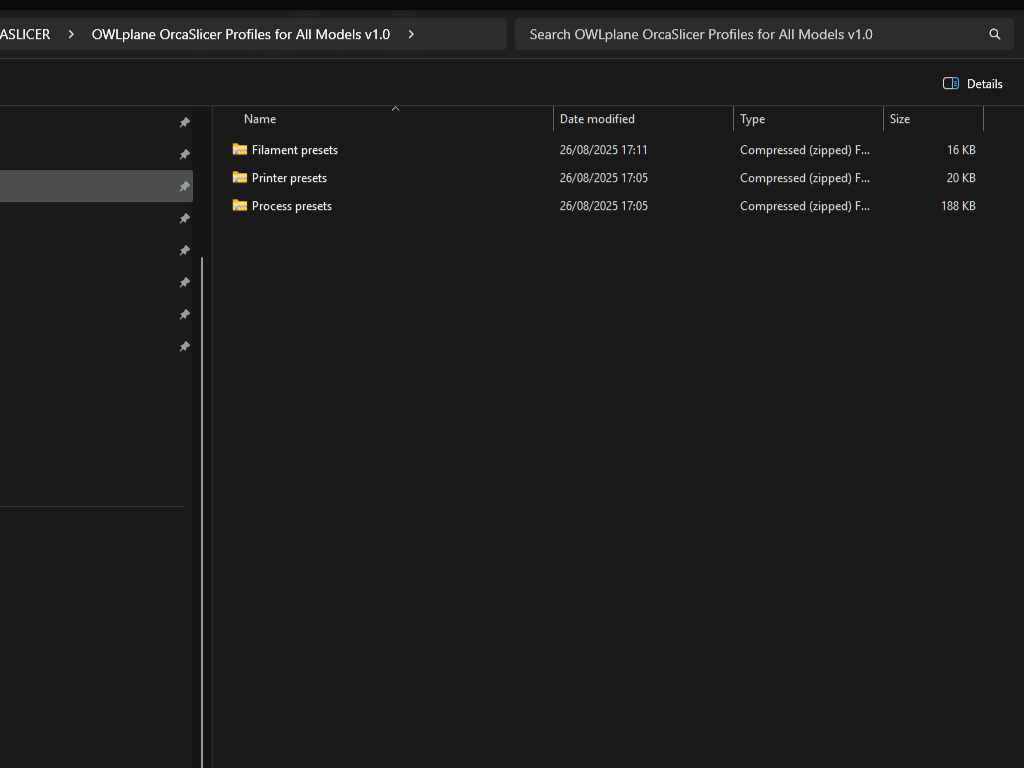

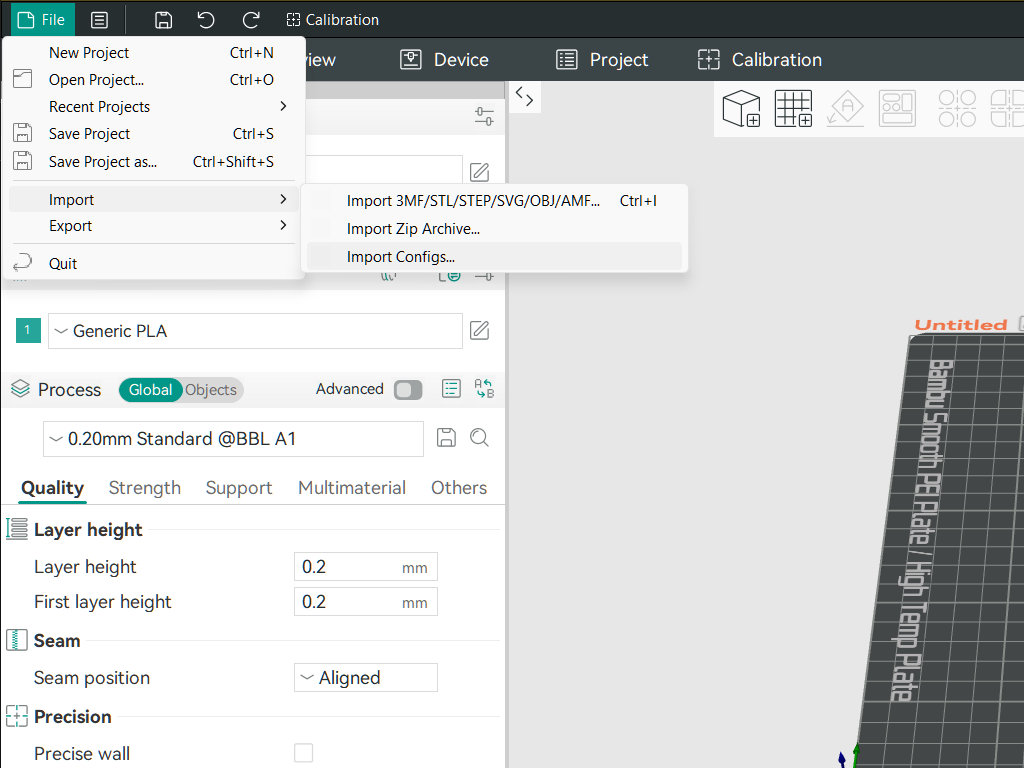

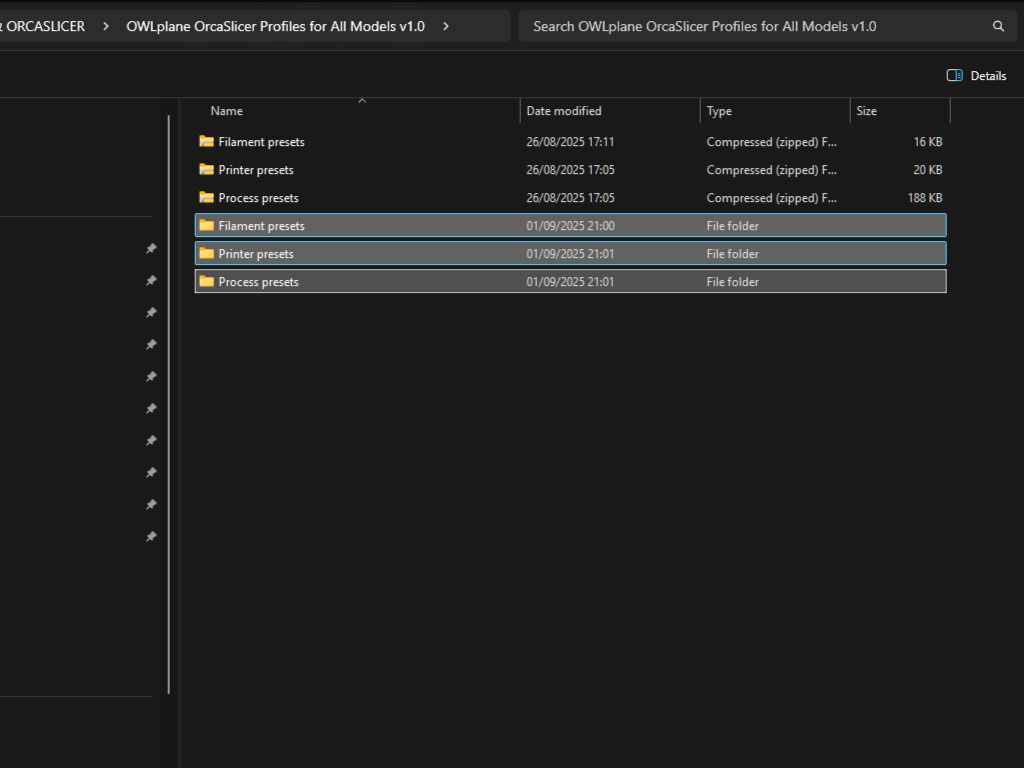

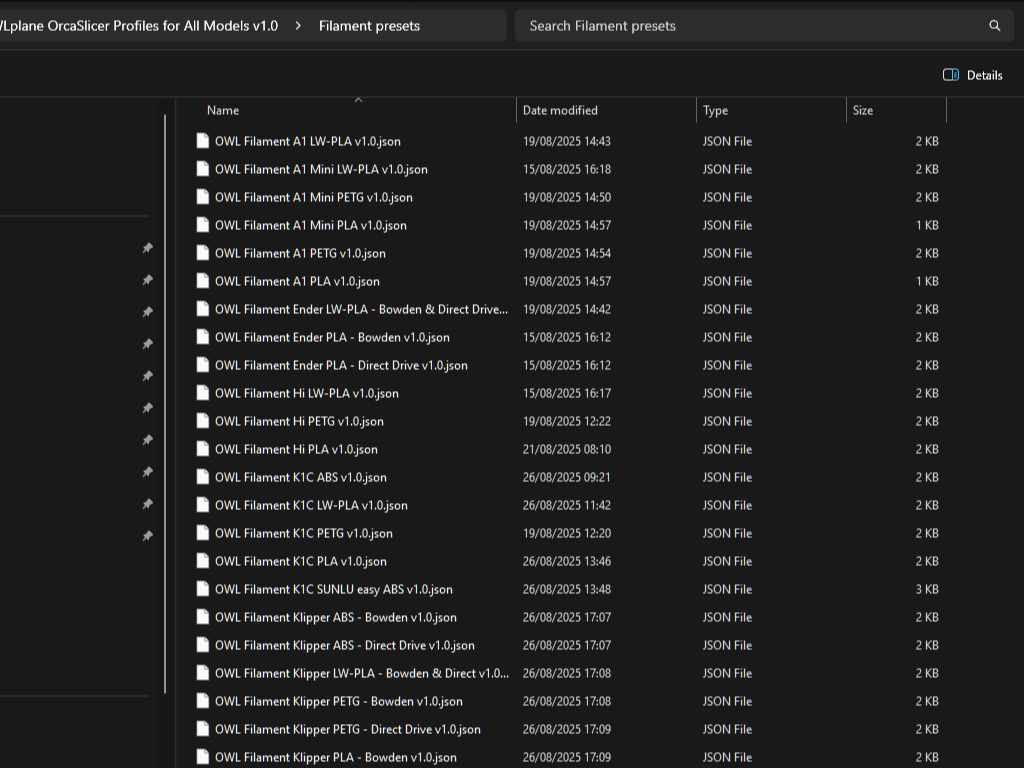

Import Config Zip Files ( 1st Method )

There are two methods to setup the OWLplane Profiles for your already installed OrcaSlicer. The first one is to use “importing tools” and the second one is to copy all profile config files into the target config directories.

Just follow the following video on how to import config files. This 1st method is the quickest method on how to set your OrcaSlicer ready slicing and printing OWLplane model STL files.

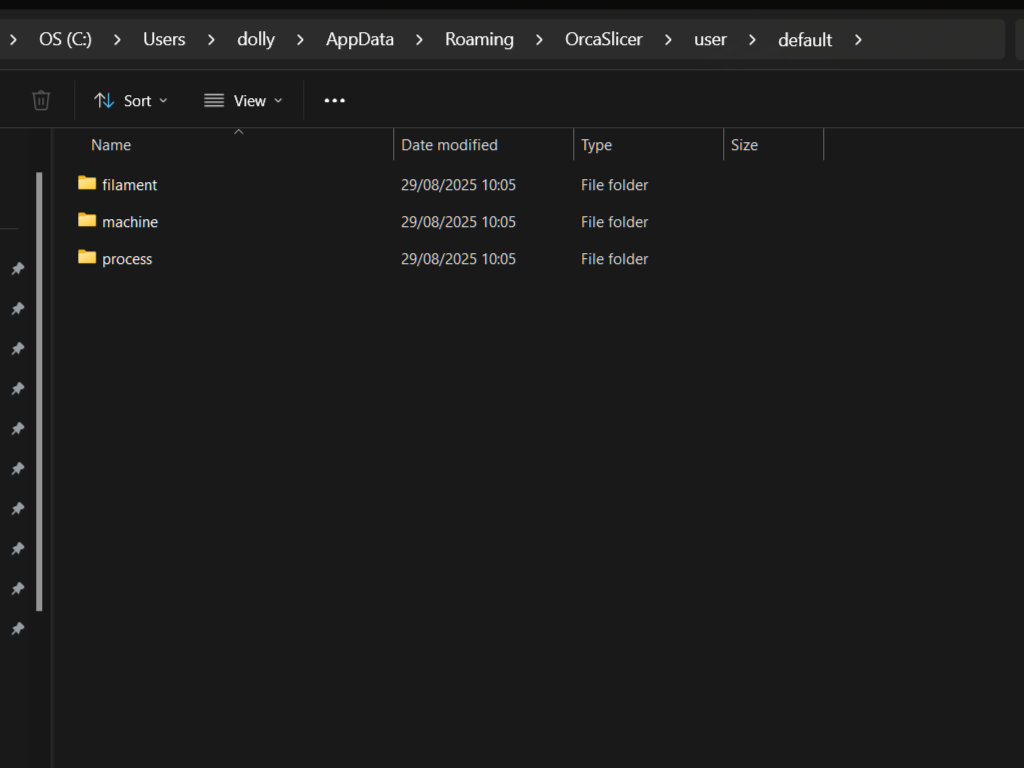

Copy Profile Config Files ( 2nd Method )

The second method to configure OrcaSlicer OWLplane profiles is by copying the individual profile files into the destination directoy. The following video shows how to.

Manual Profile Creation (For Other 3D Printer Machines)

If your 3D printers are not found in OWLplane profile files, what you need to do :

(1). Add your 3D printer to OrcaSlicer (you can follow the above video)

(2). Create a new machine inherits from your just added 3D printer (if necessary), new filament inherits from “Generic PLA, PETG or ABS” filament profiles and a new process inherit from (default) “0.20mm standard” process to be updated by following one of sample from existing provided OWLplane machine, filament and process profiles whenever necessary.

Note : always turn off aux fan !

(3). Try to update but keep some values specific only to your 3D printer characteristics/specification.

(4). After updating, you may compare just a newly created profile with some sample profiles to review.

(5). Do the iteration by starting printing your selected OWLplane STL file and improve the result gradually.

(6). Decrease or increase the 3D printer speed via “Max volumetric speed” Filament tab under Filament setting for non-active foaming filament such as PLA, PETG or ABS to get the best and optimal result.

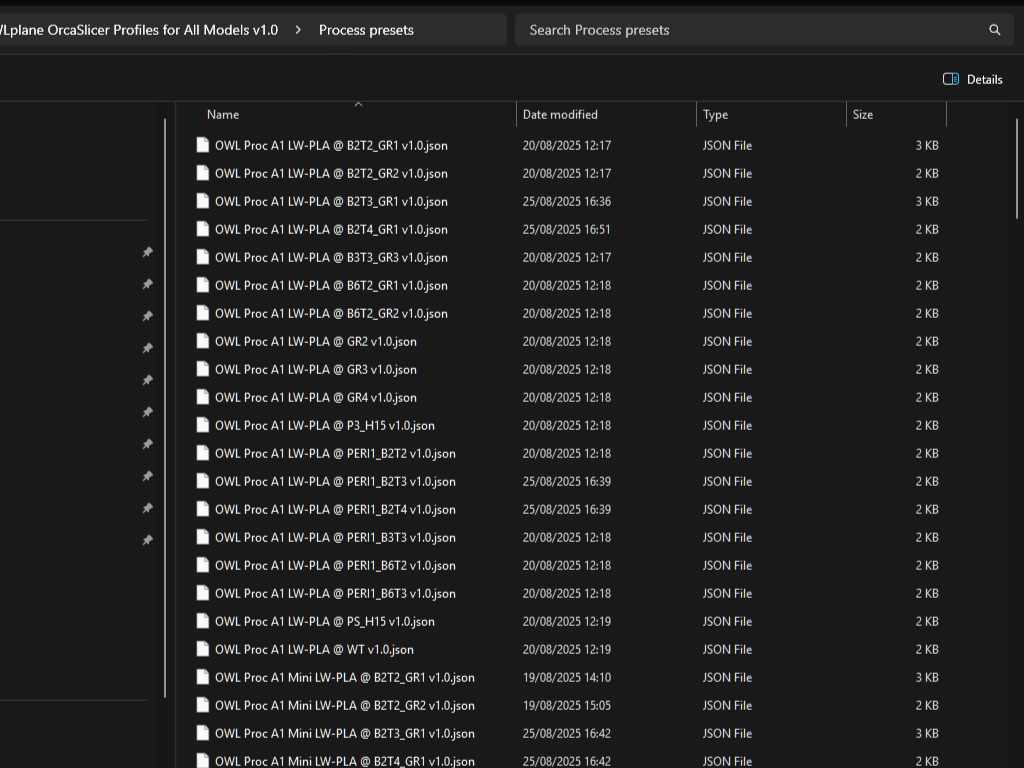

Slicing and Printing

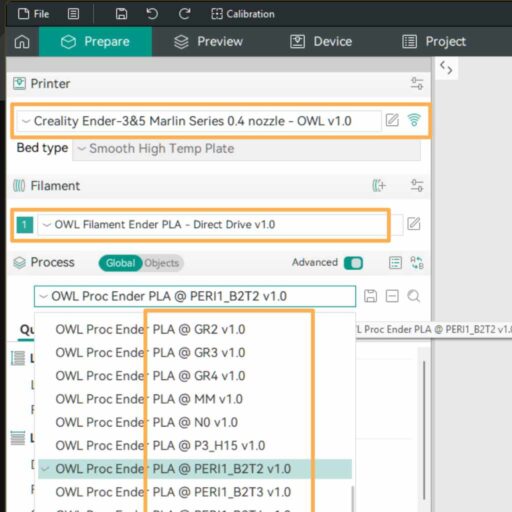

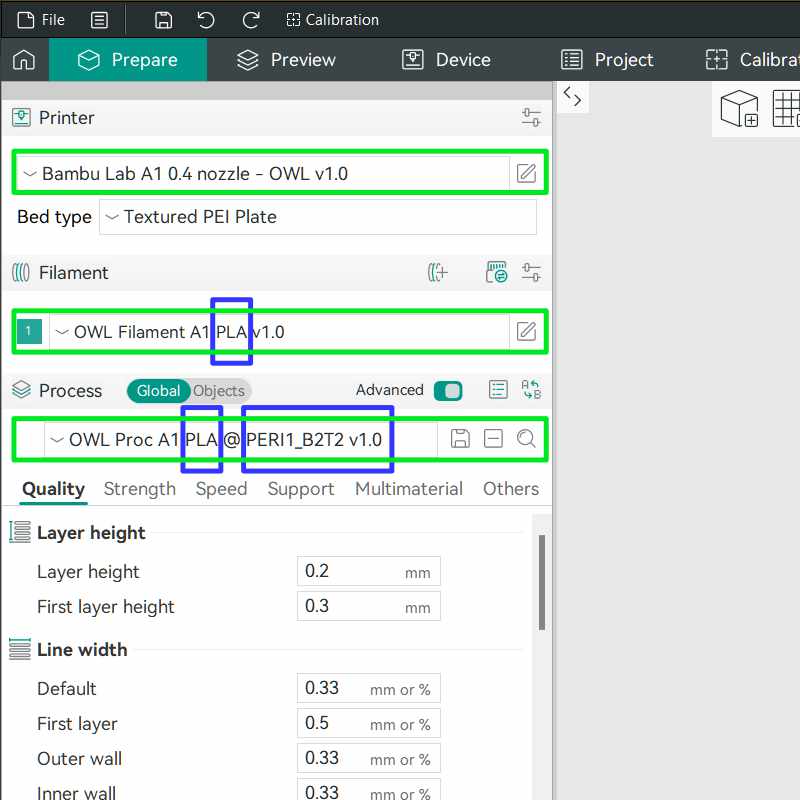

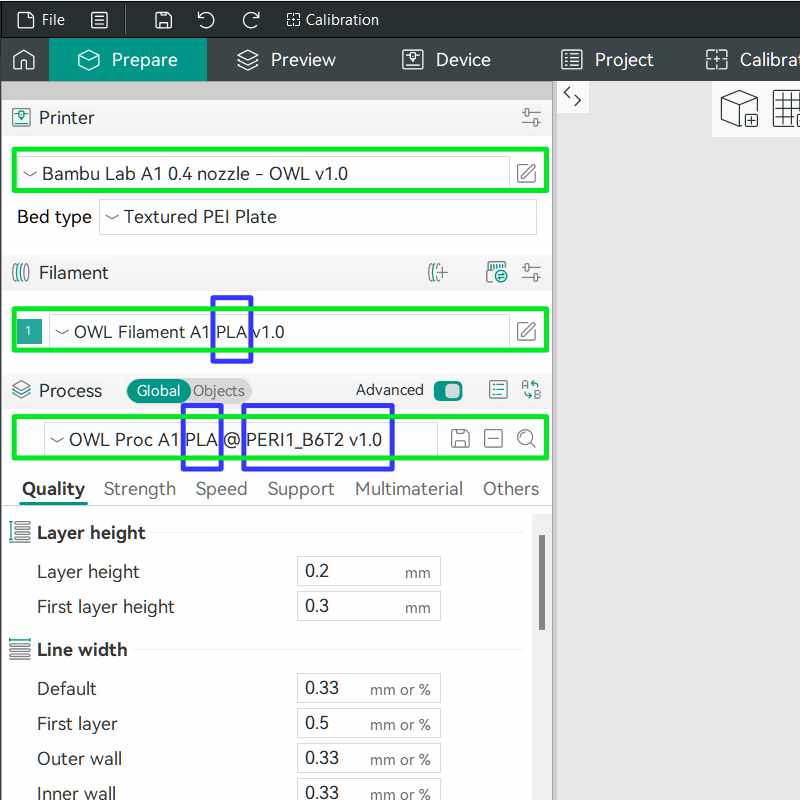

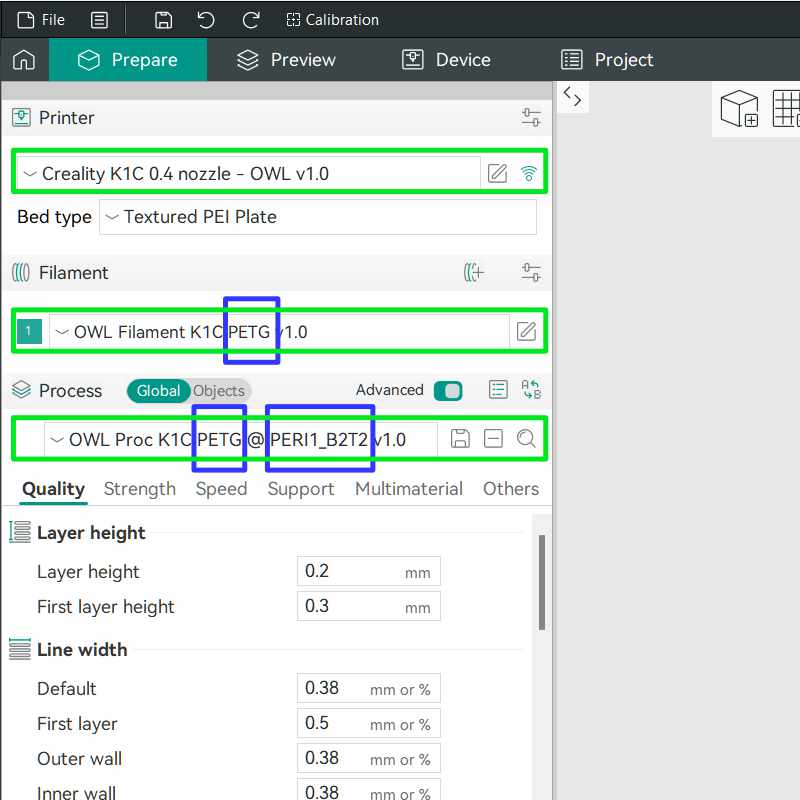

Six samples are provided below for you to get familiar with on how to slice OWLplane STL files. You need to prepare and select what machine, what filament and what process corresponding to your 3D printer machine, filament type that you use and process that follow reference code right after “#” character.

– Printing a reference code PER1_B2T2 STL file using PLA filament on BambuLab A1 3D printer.

– Printing reference code PER1_B6T2 STL files using PLA filament on BambuLab A1 3D printer.

– Printing reference code PER1_B2T2 STL file using PETG filament on Creality K1C 3D printer.

Other 3 sample cases with no videos also shown below,

The following video shows on how to print a reference process code PER1_B2T2 STL file using PLA filament on BambuLab A1 3D printer.

STL File : FUSELAGE-2 # PERI1_B2T2

The following video shows on how to print a reference process code PER1_B6T2 STL files using PLA filament on BambuLab A1 3D printer.

STL Files :

ELEVATOR-1-L # PERI1_B6T2

ELEVATOR-2-L # PERI1_B6T2

ELEVATOR-1-R # PERI1_B6T2

ELEVATOR-2-R # PERI1_B6T2

The following video shows on how to print a reference process code PER1_B2T2 STL files using PETG filament on Creality K1C 3D printer.

STL Files :

CANOPY-GLASS-1 # PERI1_B2T2

CANOPY-GLASS-2 # PERI1_B2T2

CANOPY-GLASS-3 # PERI1_B2T2

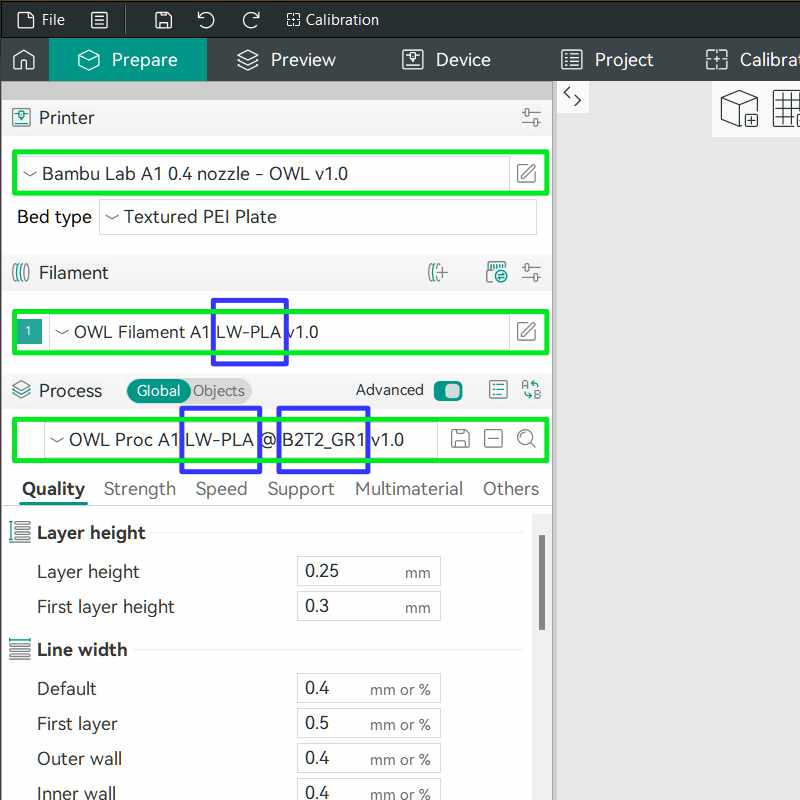

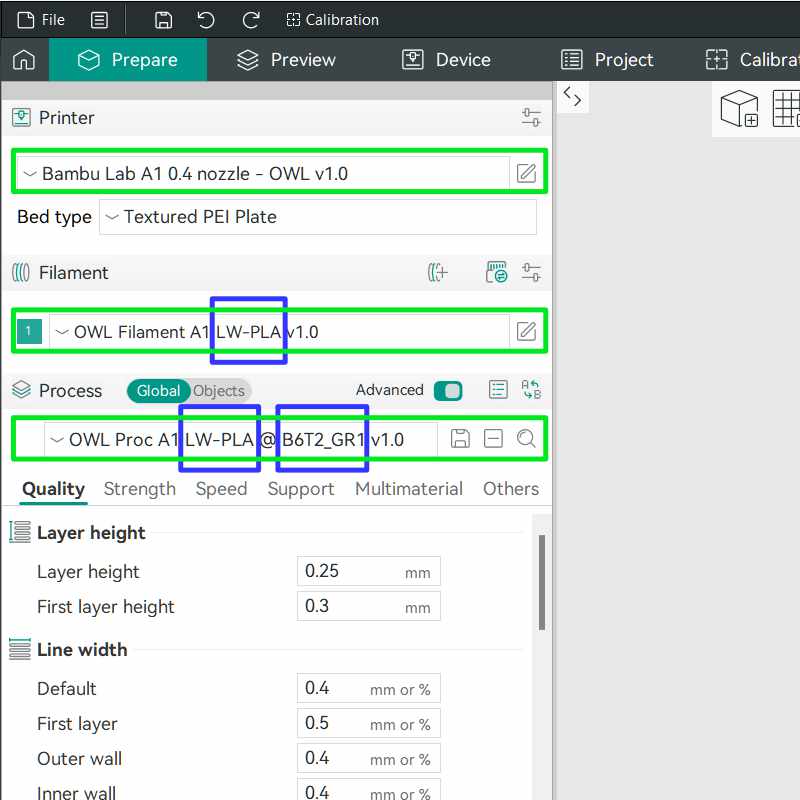

Case : BambuLab A1, printed with LW-PLA using B2T2_GR1 process.

Case : BambuLab A1, printed with LW-PLA using B6T2_GR1 process.

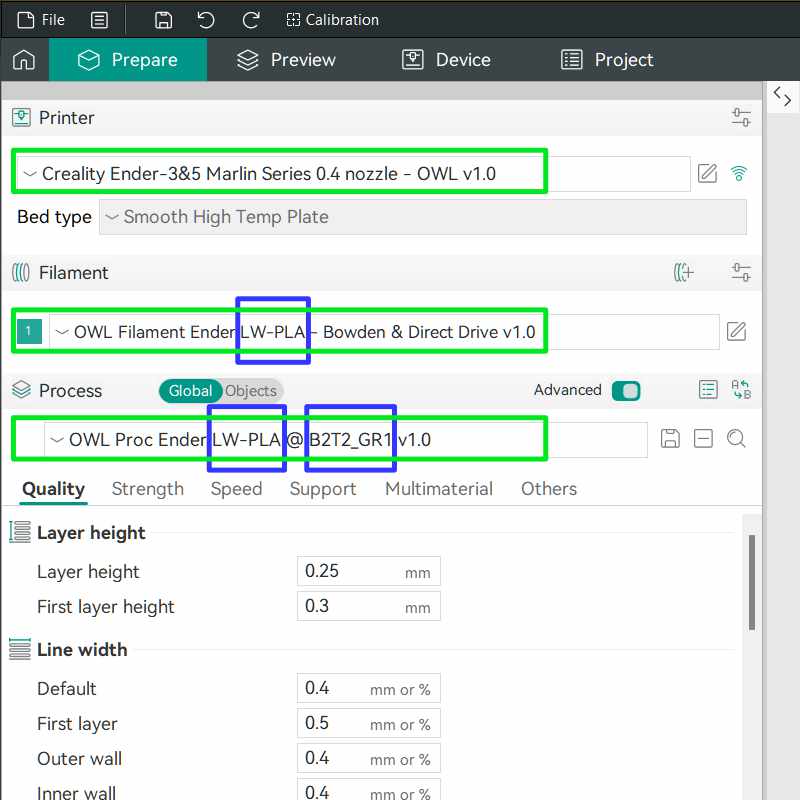

Case : Ender-3 v2, printed with LW-PLA using B2T2_GR1 process.

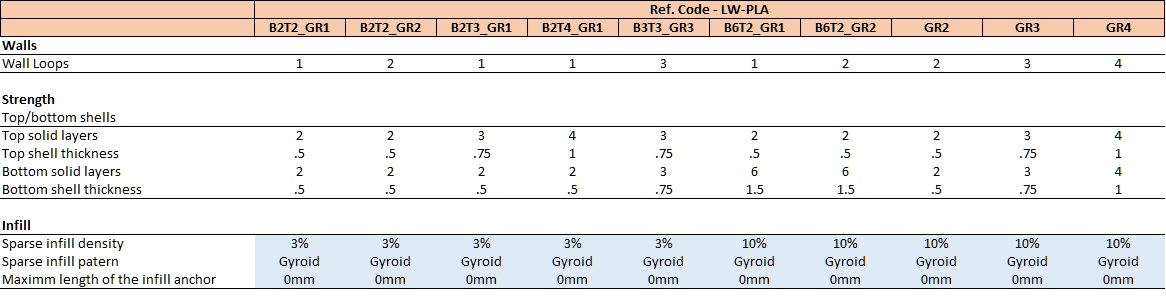

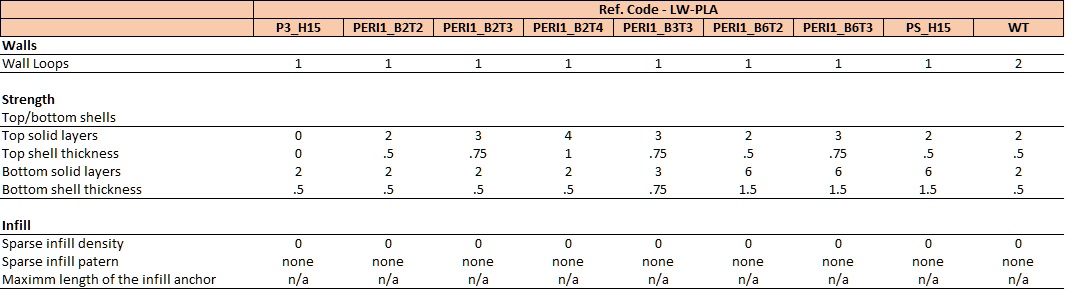

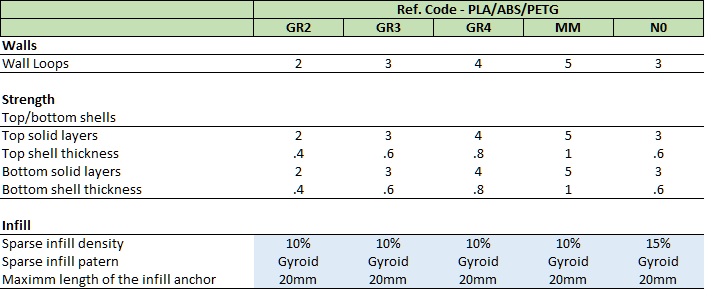

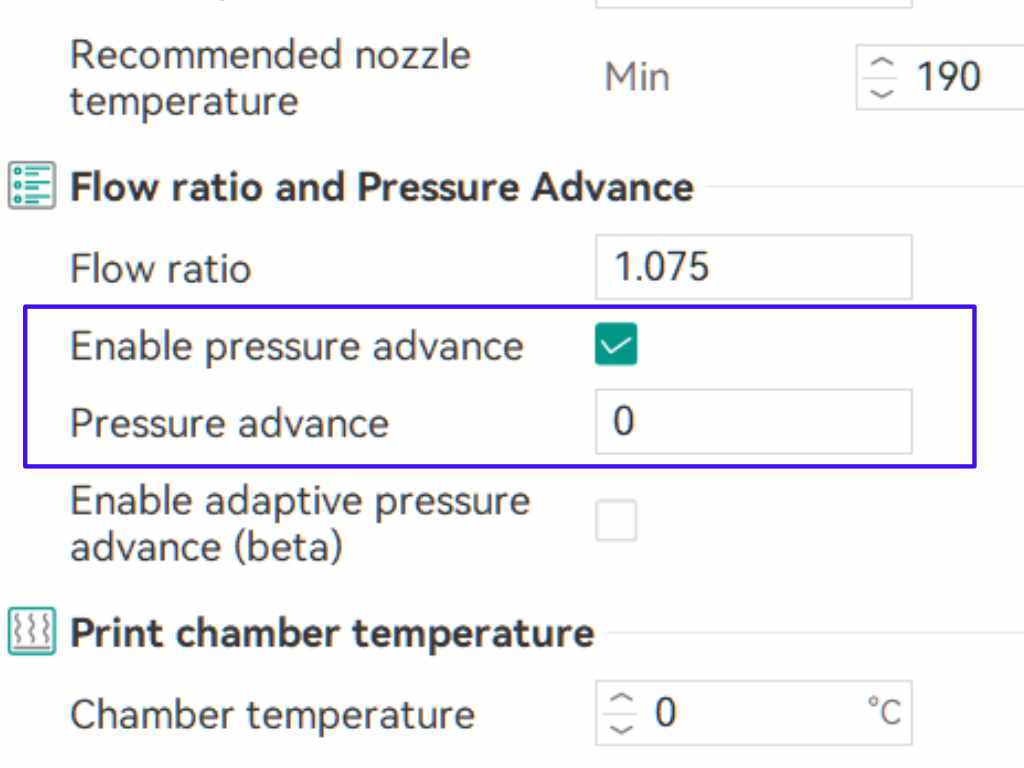

Process Ref. Code

Below explains the process reference codes set values :

OWLplane OrcaSlicer Project Sample Files

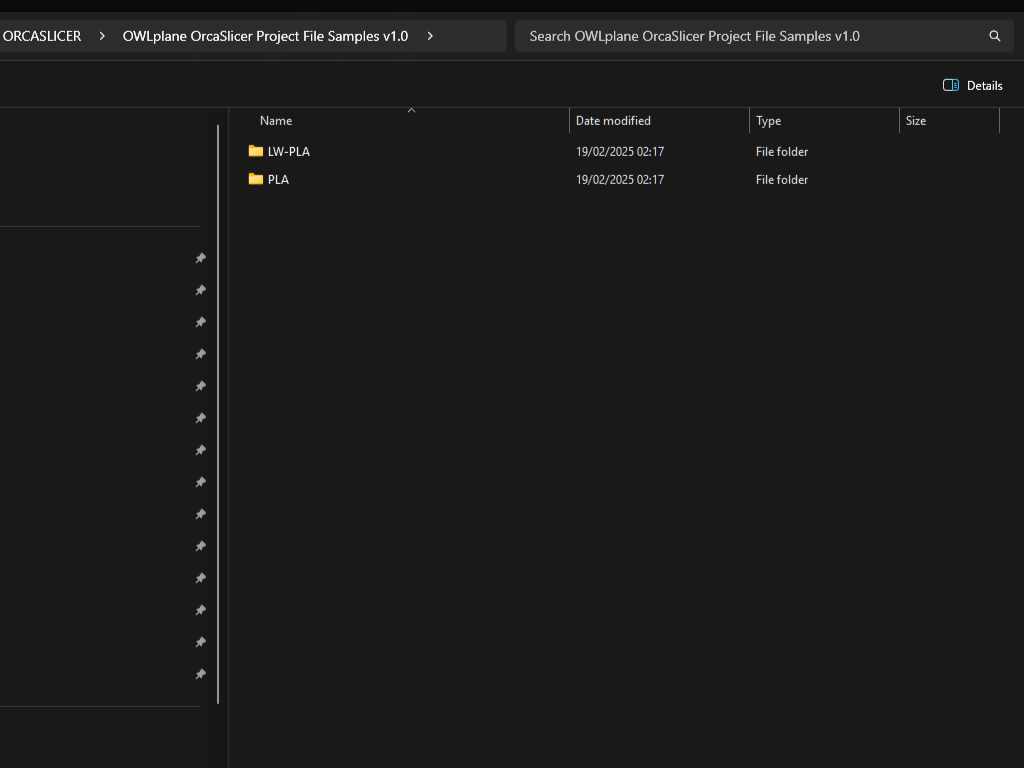

After unzipping project files, you will find two subdirectories “LW-PLA” and “PLA” as shown on the right side :

Removing Timelapse To Get Clean Preview

( BambuLab Only )

To get the clean travel view, user preset machine is created. Whenever to record the timelapse, feel free to use system preset profile.

Material Flows and Strength

Feel free to increase or decrease some setting values to get a better result. Increasing the print weight, it may usually increase the strength. Need to find the sweet spot where the strength is good enough and the weight is still acceptable

– increasing or decreasing flow rate under filament setting group.

– increasing or decreasing print line width under process setting group.

– increasing or decreasing print layer height under process setting group.

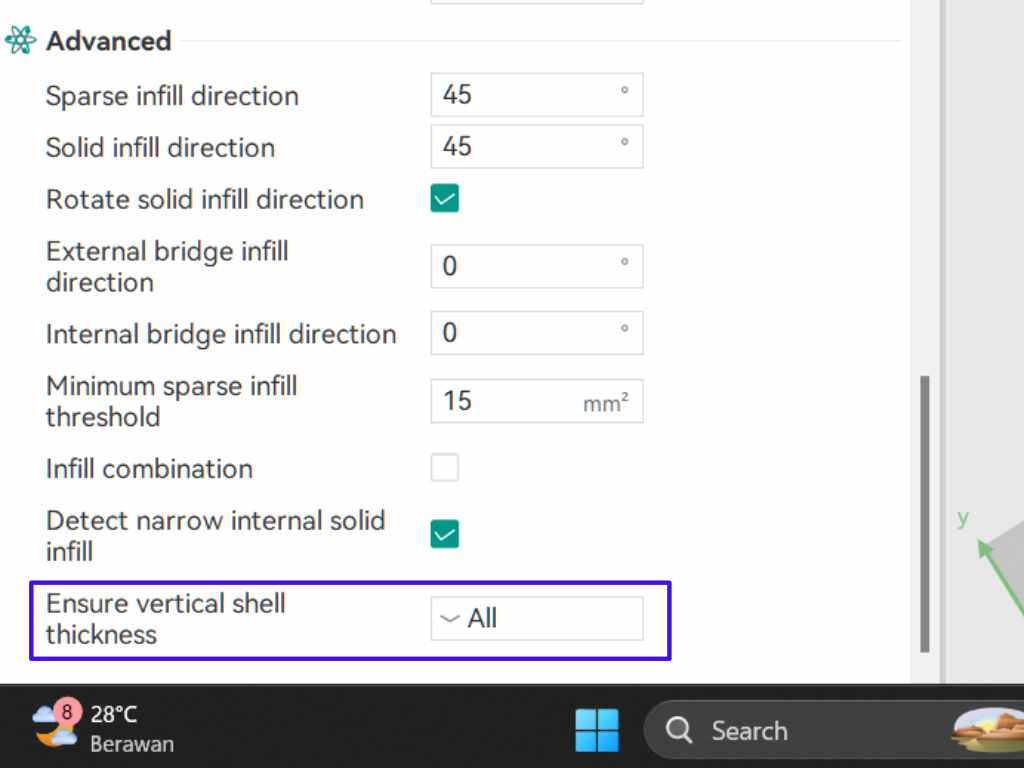

– keep ensure vertical shell thickness checked under process setting group.

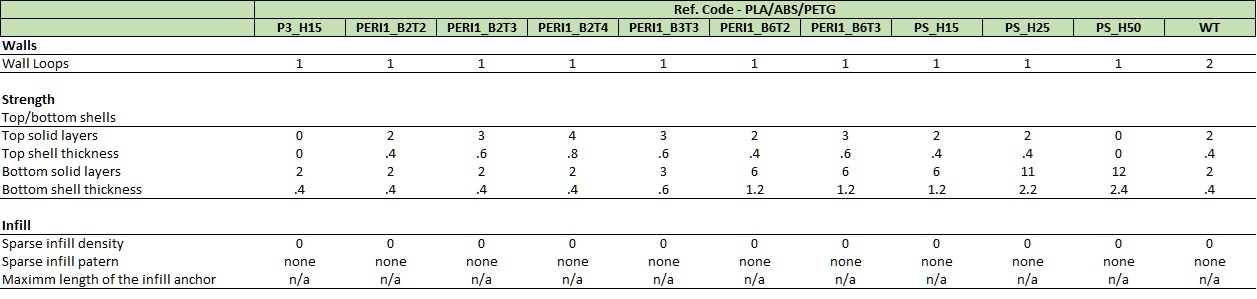

Extra length on restart for LW-PLA

For LW-PLA, it is important to compensate some missing material during travel by increasing extra length on restart under filament setting group (too high the value will increase the total print weight). On the right side, the “Extra length on restart” is set to 0.2mm.

It is important also to set the length to a small number so that there is still retraction that will trigger “Extra length on restart”. The number is set to “0.01mm” which is considered small enough.

Note : retraction function will not affect anything when using active foaming filament except compensating/adding some missing material due to the hotend travel.

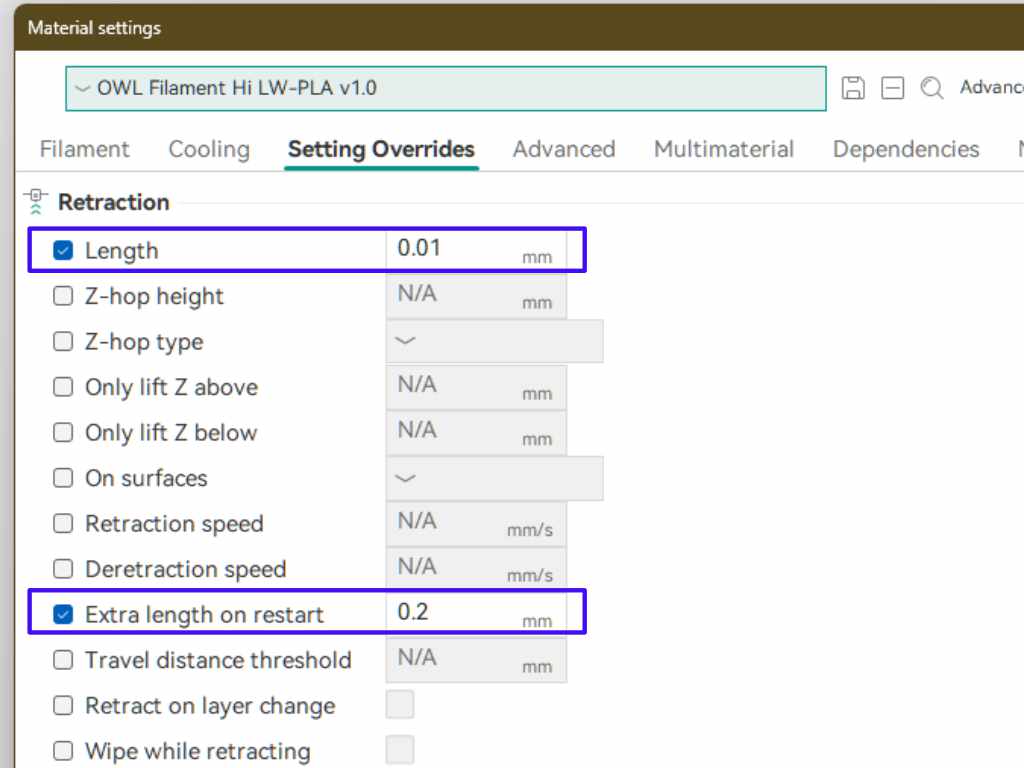

Calibrating pressure advance value under filament setting group is important if you find the model like the following :

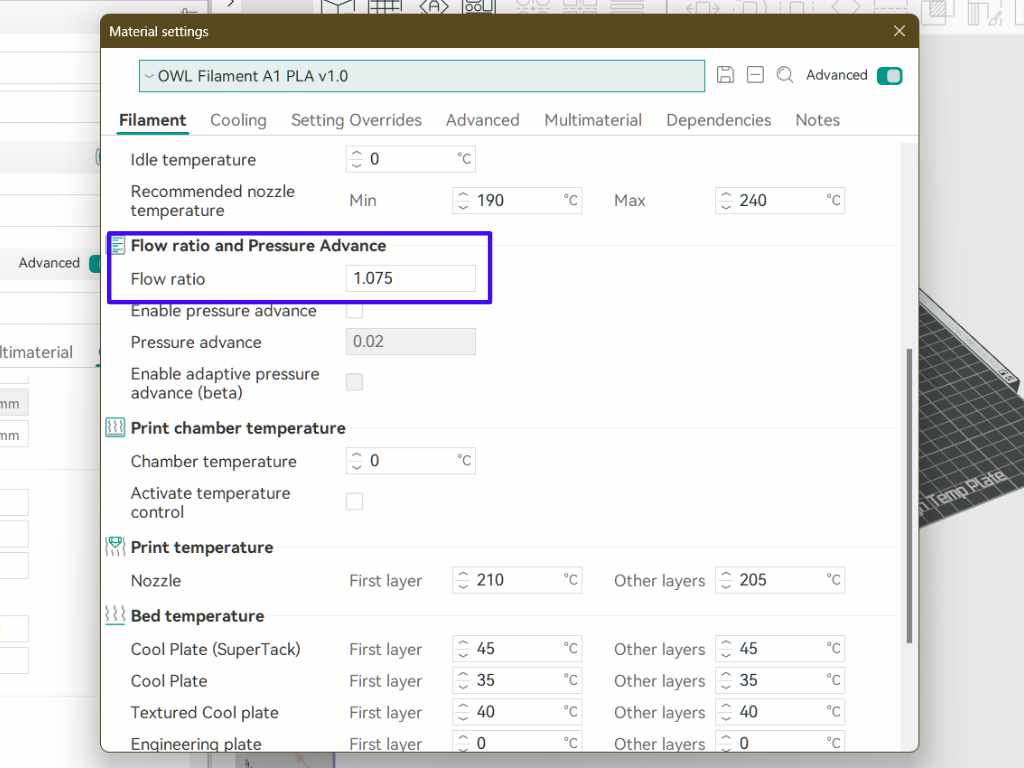

Flow ratio for non-active foaming filament such as PLA, PETG and ABS

OWLplane will start the flow rate set to 1.075. After some testing, we believe that the number is good enough to prevent the problem as shown above for some parts designed forcing “vase” mode during printing. Too high will give more weight where too low it will introduce such as the problem above. What need also to consider is the relation between layer width vs material flow. Find the best pair values so that the total weight is still good and strong enough, the weight is acceptable and no shown above problem introduced.

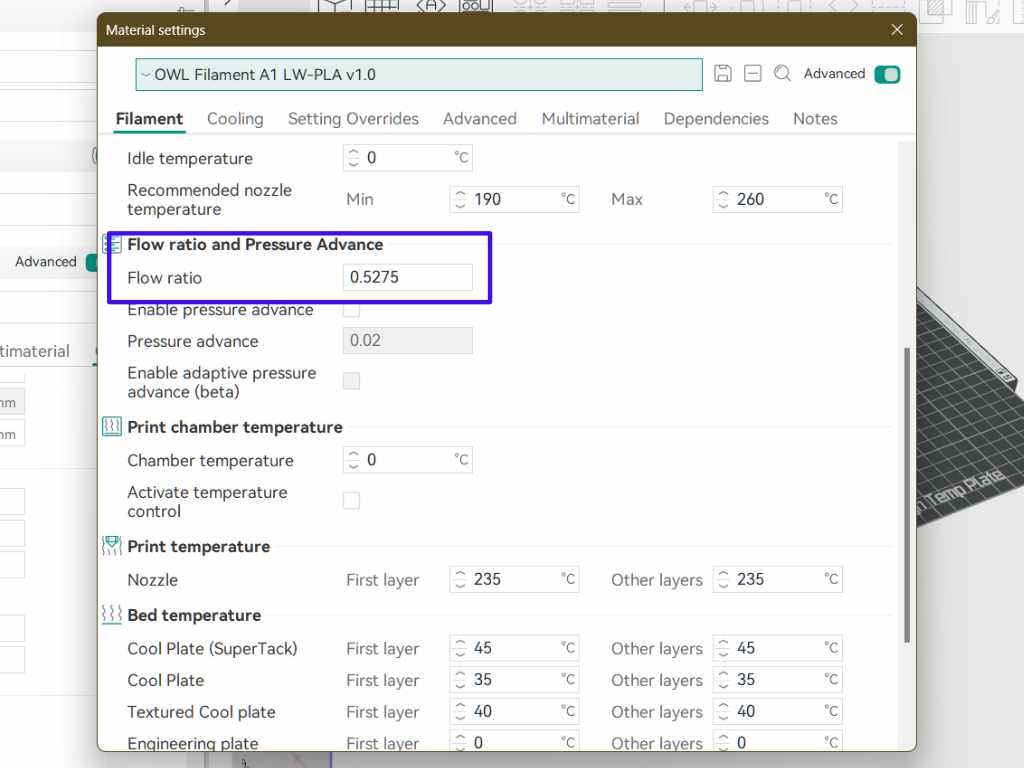

Flow ratio for active foaming filament such as LW-PLA

For active foaming filament such as LW-PLA, OWLplane will start the flow rate set to 0.5275 (far below 1.0 since the filament will expand due to active foaming material). After some testing, we believe that the number is good enough to get the acceptable strength. Too high will give more weight where too low it will get weaker printed parts. What need also to consider is the relation between layer width vs material flow. Find the best pair values so that the total weight is still good and strong enough.

Ensure vertical shell thickness

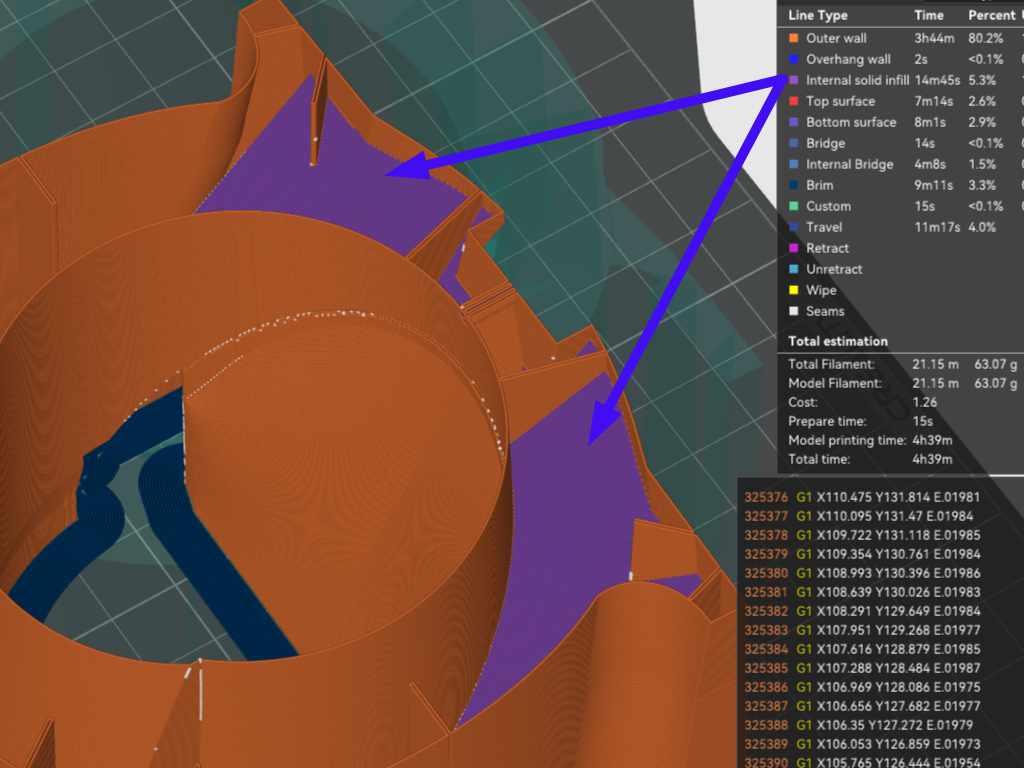

Another consideration to ensure the outer perimeter is strong enough by setting “Ensure vertical shell thickness” to “All”.

“Internal solid infill” will be introduced during printing since OrcaSlicer detect that areas shell thickness too low using a single perimeter only.

Speed and Cooling Optimization

How fast you print the parts may affect the printed result. Higher speed means less for part cooling time. Turning cooling part fan too high may weaken the printed part where layer adhesion is the most important factor for rc plane part. Lower fan part speed is better for adhesion but it may ruin the printed part and specifically when printing the bridge for example. Not only filaments have their own characteristics but also the hotends. Some hotends do have PTFE and other using all full metal material. How long is the hotend height dimension also affecting the melting process.

For PLA/ non-active foaming filament, there is quite range of speed that can be used to print. Depending on both, the 3D printer and the filament utilized and used.

For LW-PLA/ active foaming filament, the speed is limited by the filament temperature requirement. The optimal speed is found about 35mm/s to 40mm/s as per our experience. It does not matter how fast your 3D printer can print.

PLA / non-active foaming filament

New release 3D Printers (usually with Klipper firmware) is able to achieve about 150mm/s or more. High speed/ hyper filaments are type of filaments that should go with that 3D printers.

If your printers are available to achieve that speed, it is recommended to follow one of those that is closer to your 3D printer speed. They are BambuLab A1, BambuLab A1 Mini, Creality Hi or Creality K1C. DIY 3D Printer can follow a sample from “OWLplane 3D Printer 220x220x220 Klipper – OWL v1.0”.

For older or released couple years back (usually with Marlin firmware), you can follow a sample from “Creality Ender-3&5 Marlin Series 0.4 nozzle – OWL v1.0”. Just review your expected maximum 3D printing speed, if it is not far from 60mm, most likely the sample is good enough.

LW-PLA / active foaming filament

Our experience tells us that the optimal speed has range from 35mm/s to 40mm/s. It does not matter how fast is your 3D printer. It is limited by the filament speed requirement.

You will notice that process profile speed for LW-PPLA filament is set to 35mm/s for all of samples.

OWLplane uses “Volumetric speed limitation” to control 3D printer speed when using non-active foaming filament.

Depending on the filament type, feel free to increase “Max volumetric speed” when using high speed type of filament and high speed 3D printer.

Hotend Temperature Optimization

Type of filaments may have their own requirements. It is suggested to follow the manufacture suggestion for the first print. Try gradually increasing or decreasing the hotend temperature whenever necessary. Not only type of filament but also type of hotend or 3D Printer brand and type, even the same brand, it may have different optimal / best hotend temperature but usually not much.

During our testing we found the optimal temperature as follow, when printed with PLA :

BambuLab A1 : 205C, BambuLab A1 Mini : 205C, Creality Ender-3 v2 : 205C, Creality Hi : 205C, Creality K1C : 205C, DIY ZeroG and/or Voron EnderWire using TZ 2.0 hotend : 205.

During our testing we found the optimal temperature as follow, when printed with LW-PLA :

BambuLab A1 : 235C, BambuLab A1 Mini : 235C, Creality Ender-3 v2 : 235C, Creality Hi : 230C, Creality K1C : 230C, DIY ZeroG and/or Voron EnderWire using TZ 2.0 hotend : 235.

Heatbed Temperature Optimization

Type of filaments may have their own requirements when pair with type of heatbed. Just follow the requirement but please notice that the higher setting temperature may affect the bottom side of the part (small dent may appear). It is suggested to follow the manufacture temperature suggestion for the first print and decrease or increase gradually when needed.

Creating Smoother Top Layer

The top layer may affect the gluing process where smoother top layer may get better adhesion compared to rough top surfaces. More layer may means getting smoother top layer. Feel free to have more than 2 layers but please consider the additional weight introduced if more than 2 top layers are introduced. Below, it shows how 2 to 4 layers may affect the final result of the top most parts.

From right to left :

Numbers of top layers used are 2,3,4 and 5 respectively.

The right most top layer part is the roughest where the left most is the smoothest.

For sure, the right most is the lightest and the left most is the heaviest.

Easier to clean before gluing is the left most and where the right most needs some work by sanding before gluing.

Printing With Infill (No Internal Ribs), Experimental

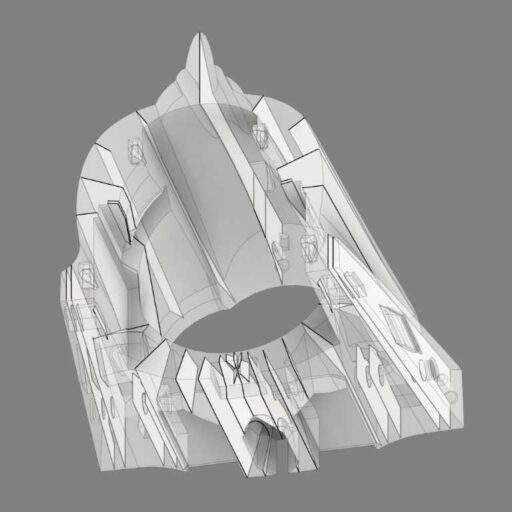

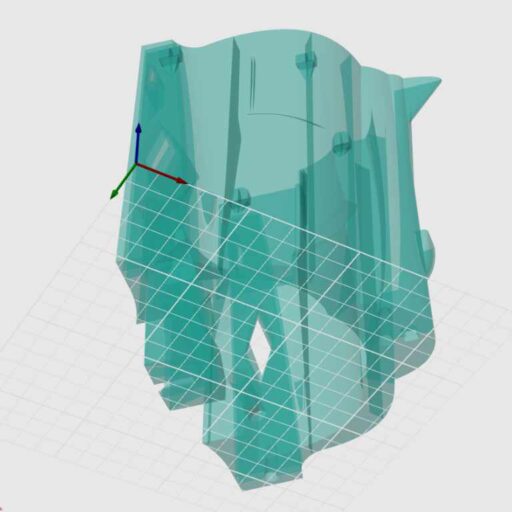

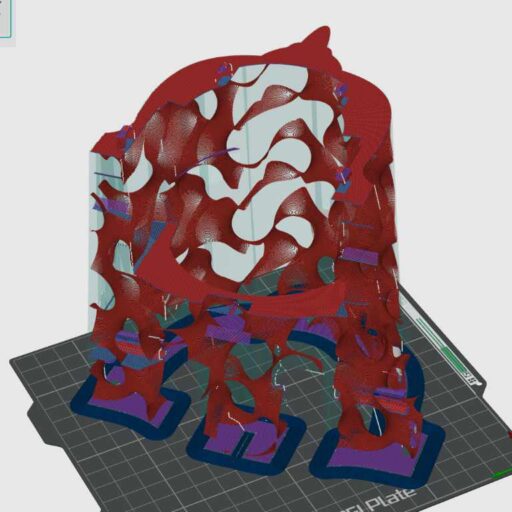

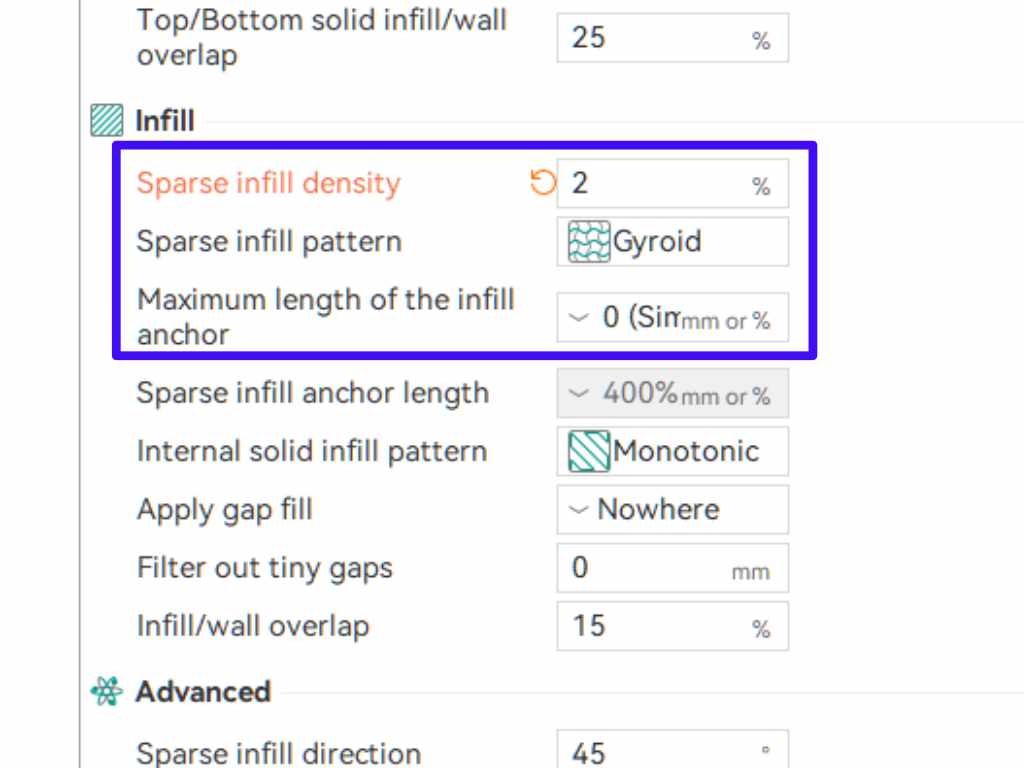

Feel free if you would like to print with infill only and no internal ribs. OrcaSlicer is able to remove the internal ribs by setting one of the parameter (see below). The infill percentage can be set from 2% – 6 (start with only 2% for non-active foaming filament) depending on the filament types, the size of the parts (how small or big), the layer height and width also can contribute to the final strength result. The infill parts can be stronger or better compared to the original design. The pictures below show when the part designed with internal ribs, as shown from the left most and picture in the middle, when sliced with not internal ribs, its internal will be replaced with the infill (in this case is gyroid infill).

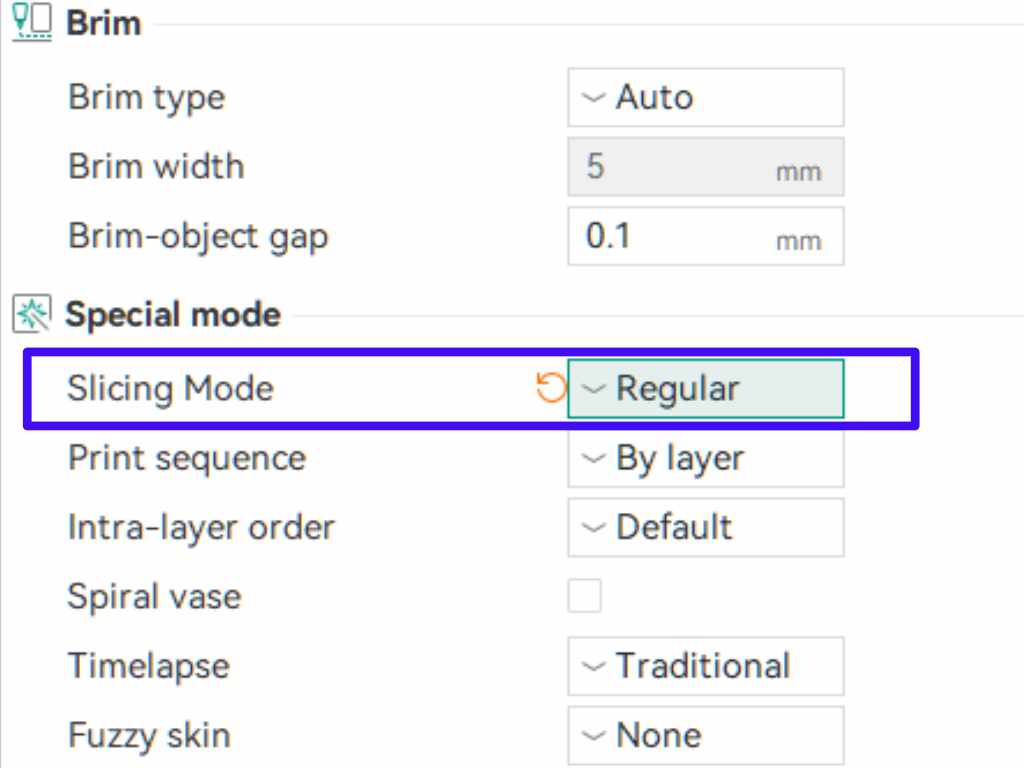

To remove the internals, need to replace “Slicing Mode” from “Even-odd” into “Regular” under “Others” tab in Process.

Try to find the best value for “Sparse infill density” and to reduce more weight the “Maximum length of the infill anchor” is set to 0 (recommended).

It is up to you to find the best ratio between strength vs weight.

Table of Contents

Let The Default Speed & Adjust It Via Volumetric (For Non-Active Foaming Filaments, Such As Standard PLA, PETG, ABS, Etc.)

Case : Ender-3 v2 w/ LW-PLA using B2T2_GR1